Commercial Panel Maintenance: A How-To Guide

The most common misconception about commercial solar in the Philippines is that it is "install and forget."

While solar is low-maintenance compared to a diesel genset, it is not no-maintenance. In Metro Manila's dusty environment or the salt-spray coastal zones of Cebu and Davao, a neglected system can lose 15% to 25% of its generation potential. For a 100kWp business system, that’s tens of thousands of pesos in lost savings every month.

The good news? Keeping your system healthy doesn't require rocket science. It requires a schedule.

This guide outlines practical, Philippine-context maintenance protocols for business owners and facility managers.

1. The Enemy: Soiling and Hotspots

In the Philippines, we battle specific environmental factors:

Urban Pollution: Diesel soot from jeepneys and trucks creates a sticky film on panels in NCR. Rain doesn't wash this off; you need to scrub it.

Bird Droppings: One well-placed dropping can create a "hotspot." It shades a single cell, causing it to heat up as the current tries to bypass it. Over time, this can burn the backsheet and ruin the panel.

Vegetation: In provincial plants, fast-growing vines or bamboo can shade panels within weeks during the rainy season.

The Financial Impact

A dirty panel doesn't just produce less power; it confuses the string inverter's MPPT (Maximum Power Point Tracking), dragging down the performance of the entire string. If you have 20 panels in a series and one is covered in bird droppings, all 20 might suffer.

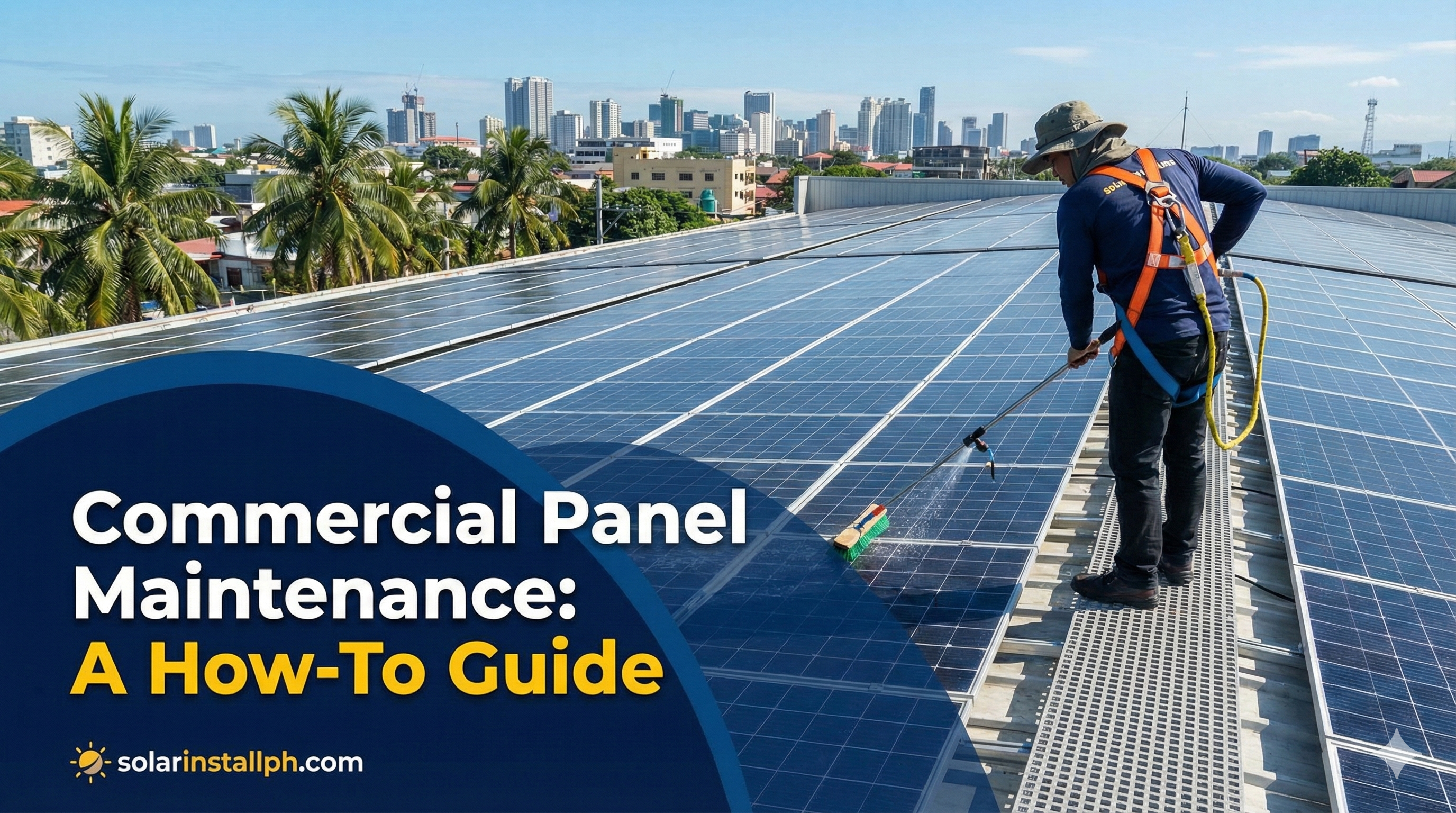

2. Safety First: The Golden Rules

Before sending your maintenance staff up to the roof, you must establish safety protocols. Falling off a warehouse roof is a fatal risk.

Shutdown Procedure: Always turn off the AC Breaker and the DC Disconnect before cleaning. Water and high-voltage DC electricity are a dangerous mix.

Time of Day: Never clean panels at noon.

Risk 1: Thermal Shock. Pouring cold tap water on a panel baking at 70°C can shatter the glass.

Risk 2: Heat Stroke. Your staff should not be on a metal roof between 10:00 AM and 3:00 PM.

Best Time: 6:00 AM to 8:00 AM or after 4:30 PM.

PPE: Personnel must use safety harnesses anchored to a lifeline. Walking on solar panels is strictly forbidden—it causes "micro-cracks" invisible to the naked eye but fatal to the panel's efficiency.

For a deeper dive into safety standards, check our article on solar installation safety which covers basic electrical precautions.

3. Cleaning Protocol (The "How-To")

You don't need expensive robots. For most Philippine SMEs, manual cleaning is the most cost-effective method.

Equipment Needed

Soft-bristled brush with a long telescopic pole (do not use stiff brooms; they scratch the anti-reflective coating).

Squeegee (optional, but good for avoiding water spots).

Running water (a standard hose is fine; do not use a high-pressure washer as it can damage the silicone seals).

The Process

Inspect First: Look for loose wires, cracked glass, or signs of burning before you start wetting things.

Rinse: Spray the panels to loosen loose dust and cool the glass slightly.

Scrub: Use the wet soft brush to agitate the dirt. Focus on the bottom edge of the panel frame where mud tends to cake.

Rinse Again: Wash away the soapy water immediately. Do not let it dry.

No Detergents: Usually, water is enough. If you have greasy pollution (near a highway), use a tiny amount of mild, pH-neutral soap (like dishwashing liquid). Never use bleach or abrasive chemicals.

4. Electrical Inspections (The "Preventive" Side)

Cleaning is only half the battle. Electrical faults cause fires. Every 6 months, a qualified electrician or your O&M provider should check:

DC Cables and Conduits

Philippine heat and UV radiation are brutal on plastics. Check the MC4 connectors and cables. Are they zip-tied up off the roof?

Red Flag: Cables resting on the hot metal roof will eventually melt their insulation, leading to ground faults.

The Inverter Check

The inverter is the brain.

Clean the Fans: Most commercial inverters have cooling fans. If these get clogged with dust, the inverter will overheat and "derate" (throttle down) its power output.

Check the Screen: Look for error codes. Common ones include "Isolation Fault" (usually moisture in a connector) or "Grid Voltage High."

If you are seeing errors, refer to our guide on top inverter brands to understand what support your specific unit might need.

5. Monitoring: The Lazy Man’s Maintenance

The best way to maintain your system is to watch your app.

Huawei / Sungrow / Growatt Apps: All modern inverters come with wifi monitoring.

The "Sunny Day" Test: On a perfectly clear noon, check your peak output. If you have a 100kW system, you should see at least 80kW-90kW. If you only see 60kW on a sunny day, something is wrong.

If you notice a sudden drop, don't guess. Call your installer. It could be a blown fuse or a melted connector.

6. Maintenance Schedule for PH Businesses

Here is a realistic schedule for a typical Metro Manila or provincial business:

Frequency | Task | Who Does It? |

Weekly | Check Monitoring App for errors or zero-production. | Admin Staff |

Quarterly | Visual Inspection (walk the roof, check for debris/damage). | Maintenance Staff |

Every 6 Months | Panel Cleaning (Scrub and Wash). Do this before and after the rainy season. | Maintenance / 3rd Party |

Annually | Electrical Torque Check (Tighten AC/DC breakers) & Thermal Scan. | Qualified Electrician |

Pro Tip: Schedule your cleaning in late May (before the typhoons start) and late December (after the rainy season ends).

7. When to Call the Pros

You can handle cleaning internally, but you should budget for a professional "Health Check" once a year.

Thermal Imaging: Pros use drone or handheld thermal cameras to spot hotspots that you can't see with your eyes.

IV Curve Tracing: This diagnostic test checks the health of the solar cells themselves.

If your system is under a Performance Guarantee (common in PPAs), the provider handles this. If you own the system (CapEx), this is your responsibility. Read more about ownership models in our financing options guide.

Conclusion

A well-maintained commercial solar system in the Philippines should last 25 years. A neglected one might fail in 10.

The cost of maintenance—roughly ₱500 to ₱1,000 per year per kilowatt for professional services, or much less if done in-house—is tiny compared to the savings.

Action Item: Put "Solar Panel Cleaning" on your facility's recurring Outlook calendar today. If you haven't cleaned them in 6 months, you are likely throwing away 10% of your power.

For more details on what to expect during the installation and handoff phase, which sets the stage for easy maintenance, read our guide on commercial solar cost.